What You Need to Know About Fuel Scrubbing for Commercial Standby Generators

Posted by Kristopher Schwind

Standby generators are a worthwhile investment for every size and type of business. They serve an important purpose—keeping your operations powered up in the midst of power outages—and will last for decades if you care for them properly.

However, when generators aren’t maintained, they are susceptible to failure.

Your commercial standby generator should stay compliant with NFPA 110 to ensure you’re prepared for any formal inspection—especially if you’re in the healthcare industry.

To maintain a reliable, long-lasting emergency generator, it’s essential to perform routine maintenance to inspect and service its critical systems.

It also means conducting routine fuel filtration on your fuel system—an often forgotten but key part of sound generator maintenance. Roughly 80% of emergency generator engine failures are caused by fuel-related issues, so the health of your fuel system should be a top priority.

Maintaining Commercial Emergency Standby Generators: A Closer Look at Fuel Filtration

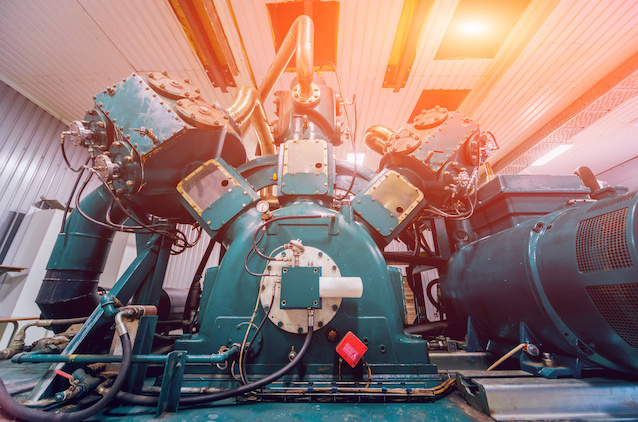

To better understand why regular fuel filtration and routine maintenance of your emergency standby generator are so important, it can help to first know how a generator works.

The backup generator system actively monitors incoming line power and, once it detects loss of utility power, automatically kicks on and transfers power from the original power source to the generator. Then, as soon as the system recognizes that power has been restored, it switches back to utility power and shuts off the generator.

(Pro tip: Part of maintaining your unit requires running the generator at least once a week for 30 to 60 minutes to ensure it’s in working order, should an outage occur.)

As you might guess, this process demands a substantial amount of work on your generator’s part. For the engine to work efficiently, not only must be it be generally well-maintained, but the fuel system—and the fuel it uses—must be clean and clear.

Mitigating Fuel-Related Engine Failures

Generator fuel systems, however, are prone to dirt, sludge and water vapor build-up, all of which contribute to fuel contamination. In addition, fuel—especially diesel—inevitably breaks down, typically within 12 months. Certain factors, such as changes in temperature, water and pressure, can speed up the process.

You can avoid these issues from occurring by having your fuel professionally tested, filtered, and polished (cleaned) on an annual basis. However, if you have a diesel generator, you may need to service the fuel system more often.

We urge you not to underestimate the power of good fuel quality: The condition of the fuel in your tanks drives your generator’s performance and can mean the difference between having power (and, thus, productivity and safety) during a power outage, and not.

In addition to regularly filtering your fuel supply, some other preventive measures you can take to promote a healthy fuel system include:

- Having your fuel system visually inspected each month

- Checking the fuel levels every month

- Replacing the fuel filter on an annual basis

The Benefits of Maintaining Your Commercial Generator

It can literally pay to take care of things, wouldn’t you agree?

With that said, perhaps the most notable benefit of conducting routine fuel filtration on your commercial standby generator and taking good care of it is the cost- and time-savings you stand to enjoy.

By not having to replace your company’s generator or pay for costly repairs due to negligence, you’re already saving tens of thousands of dollars. But what’s more is you’re also saving money and time by avoiding lost product and productivity from power outages—not to mention the time you would have spent dealing with power issues.

Partnering with a Trusted Professional to Care for Your Commercial Generator

Generators are complex machines, requiring expert care and maintenance. That’s why it’s important to work with a leading generator repair and service provider.

The most reliable way to ensure your standby generator stays compliant is by working with a service provider that specializes in fuel polishing. For example, at National Standby Repair, we not only test commercial fuel supplies, but if they fail, we conduct fuel polishing services on-site using state-of-the-art fuel scrubbing services.

For almost 40 years, businesses and consumers alike in the Tri-State area have trusted National Standby Repair to keep their generators running. Our team is committed to:

- Being experts in top-brand generators

- Delivering quality service and performance

- Offering products and services designed with our customers’ needs in mind

We’re proud to offer Annual Service Agreements to help ensure your generator is always at peak performance. Regular, scheduled maintenance visits by our expert team will guarantee that any potential malfunctions are corrected before problems arise.

Kristopher Schwind is the proud owner of National Standby Repair.

24/7 EMERGENCY GENERATOR SERVICE

24/7 EMERGENCY GENERATOR SERVICE REQUEST A QUOTE

REQUEST A QUOTE

(914) 734-1400

(914) 734-1400